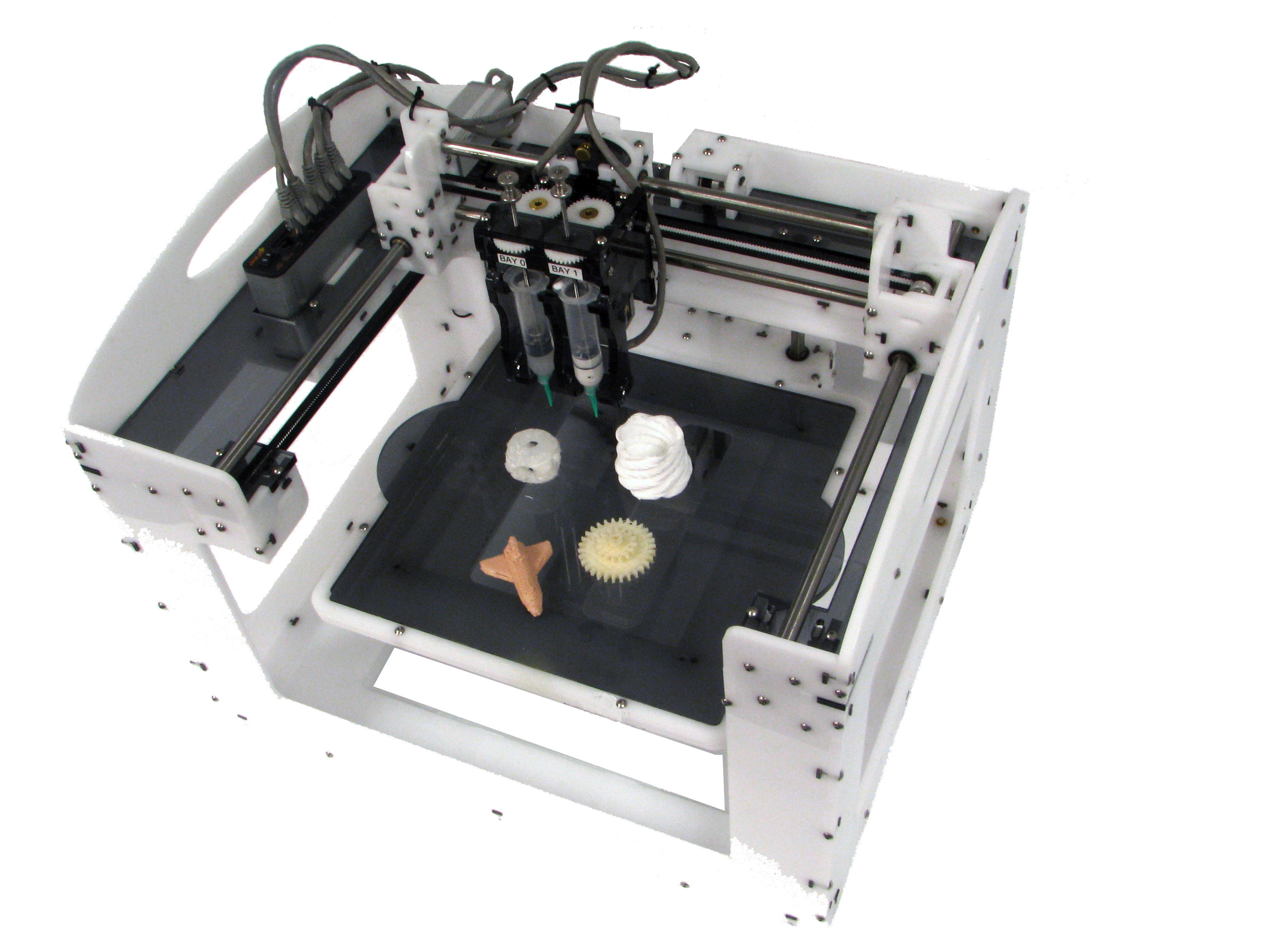

Three-dimensional (3D) printers spray thin strips of material through a specialized nozzle, forming layers that accumulate into an object described by a digital design file. They can create anything that can be imagined from solitary objects to parts used to construct a more complex object.

Three-dimensional (3D) printers spray thin strips of material through a specialized nozzle, forming layers that accumulate into an object described by a digital design file. They can create anything that can be imagined from solitary objects to parts used to construct a more complex object.

The 3D Printing, also known as additive manufacturing, is a trend that first started to become mainstream around 5-6 years ago. Back then, the next-generation of 3D printing hardware was envisioned to be a game changer in consumer electronics. Currently, this next-generation of hardware is being realized. Printing times have come down and there is more demand for the hardware and thus there is more competition in the market. Lots of startups and public companies have entered the field of 3D printing technology, an area now valued at $2 billion. With such a large growing market, specialization of the 3D printer has emerged. Some machines focus on the medical field, some on automotive components and even some on large-scale building construction.

Experts say there are five main driving forces driving innovation in this trend.

As stated in the description, if 3D printing technology can move from creating prototypes to actually manufacturing products that are ready to be sold on the market then this will be a huge game changer for manufacturing.

Will manufacturing shift away from large factories to smaller local factories? How will this effect traditional methods of factory to retail? How will it effect global import and export?

Will large scale 3D printers become wide spread in the construction industry?

The technology could have a huge effect on the medical device field. Both the price and availability of complex medical devices could improve for patients. How will this effect the healthcare industry?